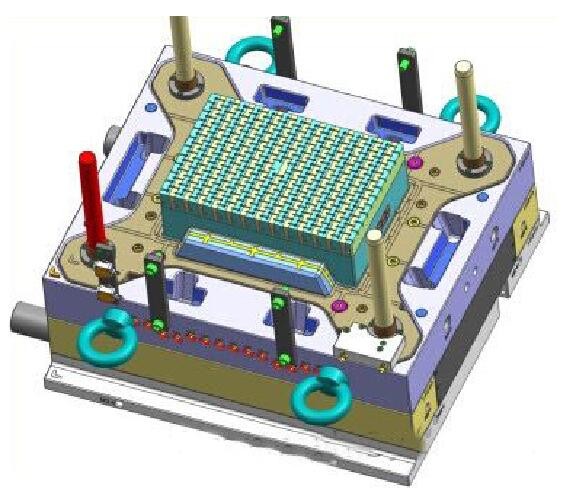

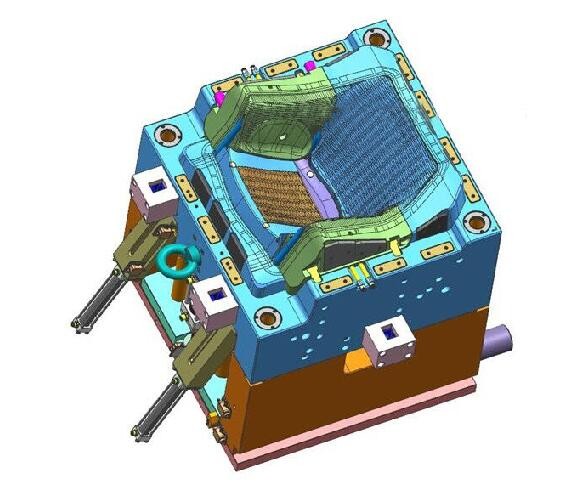

Mould Design

We have a much experienced design team, familiar with China domestic, European, American, Japanese and other mold design standards, be able to use all kinds of software skillfully for mold and product designing. There are more than 20 engineers who have much experience in mold designing:

More than 20 years experience 20%---High-level designers,

More than 10 years experience 30%--- Professional designers,

More than 5 years experience 50%--- Mold designers.

We have got a set of mature design process, from parts analysis, mold flow, structural analysis to process analysis.

And use full 3D design, With the design ability , can design more than 30 sets of complex molds monthly.

Quality Control

Quality Creates Value! At our company, quality assurance, control and monitoring procedures as philosophy are built into each aspect . Quality Control of our work, which include every step of our plastic mold making process.

• Moldflow analysis avoid potential molding issues.

• After machining, each mould component will be measured by CMM before assembly.

• Each part will be re-inspected internally.

• After machining, each mould component will be measured by CMM before assembly.

• Inspect overall function & structure of the mold before mold trial,

Fully inspection on mold trialed samples & submit FAI report to customer.

• After measuring and qualified samples with the FAI report will be submitted to customer for final approval.

• Hours automatically production without stoppage on the injection machine to test the mold running stability.

• The opening sequence of special warning plate will be stuck on the mold.

• Provide Tool Maintenance Checklist to our customers.

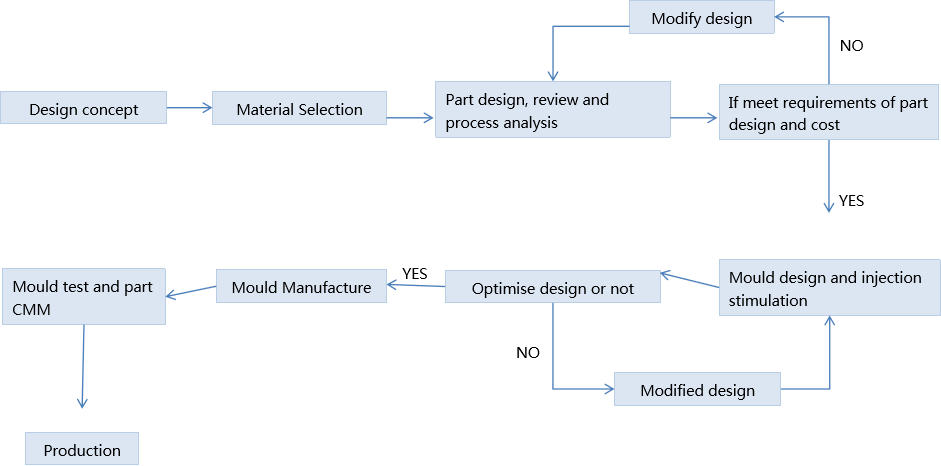

Project Flow

中文

中文

0086 136 5576 8876

0086 136 5576 8876